FARM GROWN SOLUTIONS

1. NETWRAP FACTS

TamaNet rolls are the only ones in the industry manufactured to a GUARANTEED length

- All production machines operate with calibrated metering systems, which are checked and verified, according to controlled procedures.

- Roll length is regularly measured and checked on a roll ‘un-winding unit, to verify the accuracy of the metering equipment.

- All Tama Netwrap products comply with the highest global standards.

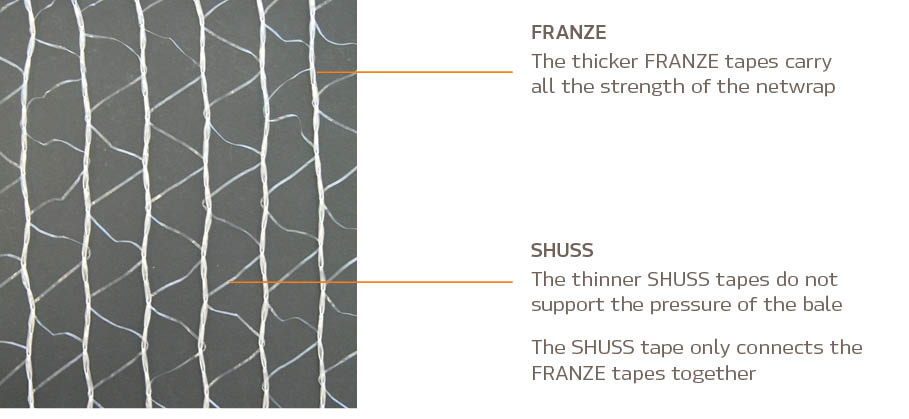

Netwrap construction

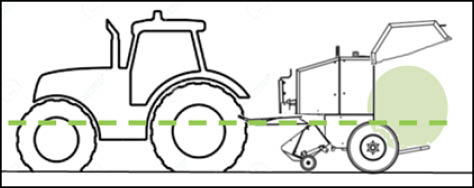

The strength of Netwrap is all in ‘Machine Direction – meaning that the thicker FRANZE tapes hold the expansion pressure of the bale.

The thinner SHUSS tapes do not support the expansion pressure of the bale; they only maintain the correct spacing of the FRANZE tapes.This can be demonstrated in this way – If the thinner SHUSS tapes are cut from the netwrap on the bale, the bale will remain intact.

The weight of the Netwrap per metre (g/m) is not related to how strong the Netwrap is.

Higher specific strength polymers, used in the manufacturing of the net, can allow the same, or even greater strength. This can make a lighter weight roll, with the same guaranteed length, from less plastic.

2. CORRECT BALING

Bale formation

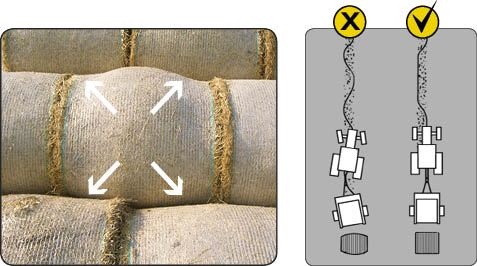

It is important that the bale shape is uniform, and flat across its surface. Un-even shaped bales will cause the Netwrap to be under greater pressure.

Net application

It is important that the netwrap is only applied on the OUTER surface of the bale. If crop is still being picked up as the Netwrap begins feeding into the baler, some of the Netwrap will be INSIDE the bale and not ON THE SURFACE.

If some of the Netwrap is ON THE INSIDE of the bale, it will create numerous problems:-

- Bale diameter will increase

- Netwrap may become damaged when bale is ejected

- Bale will not be secured fully as Netwrap is not holding the bale fully

- With fewer layers of Netwrap on the BALE SURFACE, the Netwrap may not be able to withhold the bale pressure and cause bales to burst open.

Bale damage

It is important that the bale comes out of the baler immediately that the tailgate is opened, to avoid any damage to the Netwrap on the bale surface caused by the spinning rollers in the chamber.

This is a common problem with any baler that has rollers in the bale chamber and on ALL types of Netwrap.

CAUSE

- The bale is too big and dense, and is stuck in the baler

- The bale is not able to turn easily because the chamber side walls are not shiny enough

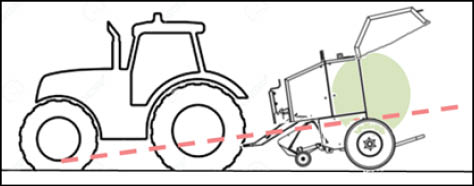

- The baler is not at the correct angle relative to the tractor, and the bale cannot eject easily

SOLUTIONS

- Reduce RPM or dis-engage PTO to the baler, which will reduce the friction of the rollers against the bale surface

- Ensure that the baler is aligned correctly relative to the tractor, to allow the bale to come out of the baler easier

Crop type

Dry, cereal crop creates more pressure on the Netwrap than a grass Hay or Silage bale

A bigger diameter bale gives MORE PRESSURE on the net and will require MORE turns of net on the bale.

Correct amount of Netwrap on the bale

It is important that the correct amount of net is applied to the bale, which can vary

depending upon a number of factors

- Crop Type

- Bale diameter

- Bale handling method

- How many times bale will be handled

It is also important to be sure that the amount of netwrap selected by the baler-monitor, in the tractor cab, is equal to the actual number of wraps applied to the surface of the bale. Many times, the amount of Netwrap on the bale surface is not what is programmed.

It is important that the correct number of wraps of Netwrap is applied to the bale, depending upon the recommended application for the particular crop.

For best baling results, it is recommended to follow this general guide.

The numbers are MINIMUM recommended layers of netwrap, on the whole surface of the bale.

| Silage 1.2m Diameter Bales |

Hay 1.5m Diameter Bales |

Straw 2.0 – 1.8m diameter Bales |

| At least 2.5 full wraps on the bale surface |

At least 3.5 full wraps on the bale surface |

At least 4.0 full wraps on the bale surface |

At least one more extra wrap of net is recommended when used in extreme conditions,

such as:

- High baler density settings

- Very short or dry crops

- Very hot temperature

- Multiple handling of the bale

- High UV conditions

- Stony fields

- Long term outside storage

!A combination of several extreme conditions may require a further increase in wraps.

These recommendations are provided as a guide. If using standard or generic Netwrap, an increase of one wrap is likely necessary to secure the bale.

Additional recommendations before and during baling:

- Check that the ends of the cardboard core are free to turn in the net box.

- Check and clean any snagging points in the baler, net feed tray, belts or ejection ramp, which may tear the net.

- During baling, load crop into the bale chamber evenly, proceeding from side to side.

- After bale ejection, ensure bale is clear of tail-gate before closing.

- Check there is no crop between layers of net on the completed bale.

3. BALER KNOWLEDGE

All round balers require the same basic parameters to operate successfully with Netwrap

- Feeding the Netwrap into the baler

- Tension the Netwrap when binding the bale

- Spread the Netwrap across the width of the bale

- Cut the Netwrap at the end of the binding cycle

Feeding system

Most balers have a system of rubber and steel rollers, with adjusting settings at each side.

It is important that both sides are adjusted equally, providing full and uniform feeding pressure between the rollers.

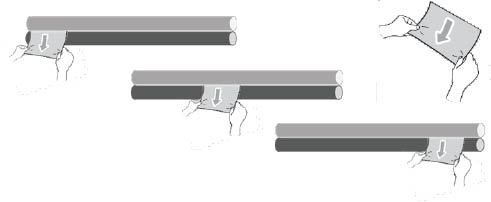

A simple check can be made to make sure the rollers are adjusted correctly and are fully parallel. Place a single sheet of paper between the rollers and turn rollers to pull the paper between.

- If the rollers are gripping tightly, pulling the paper out will slowly make the rollers turn.

- Repeat this across the width of the rollers to ensure the tension to pull the paper out is the same across the entire width.

- If the paper can pull out easier at one side than the other, adjust the rollers accordingly

Tension system

All balers need to create tension on the Netwrap as it is feeding, to be sure the netwrap will:

- spread well on the bale

- grip tightly to the bale

- allow the cutting mechanism to cut the net cleanly after binding

It is critical that the braking system is correctly adjusted and working, to ensure full and uniform tension across the full width of the Netwrap.

Depending upon the baler type and model, the Tension System could be:

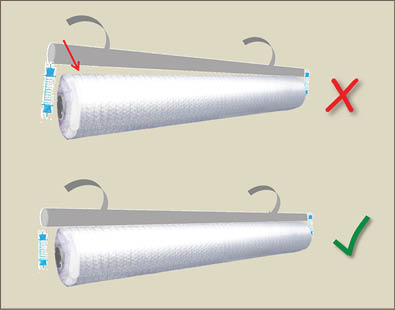

A. Spring-tension metal bar, pushing onto the Netwrap roll surface (Claas; McHale etc.)

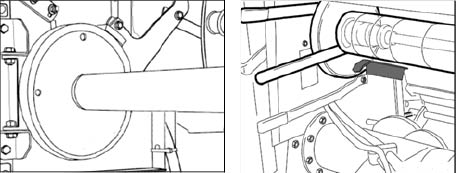

B. Braking mechanism against the Feeding Rollers (John Deere etc..)

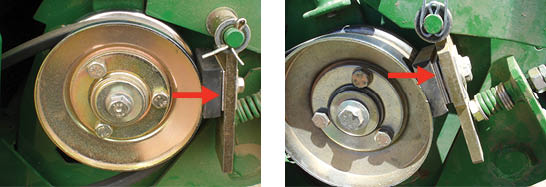

C. Disc brake and brake pad, which grips inside the card core of the Netrwap roll (Case IH; Krone; New Holland; Welger etc…)

Here are examples of the typical brake systems on common baler types and the important points to check:

Ensure that tension brake bar is flat and in contact with full width of Netwrap roll

Brake tension can be increased by more shims behind the fixing plate.

Also – be sure to check the feeding rollers are adjusted uniformly (see previous section – Feeding System)

Ensure that brake pad is not worn out, to ensure good braking efficiency

On Krone baler (picture on RIGHT) ensure the netwrap brake arm is in position and adjusted per operator manual

4. BALER KNOWLEDGE – TROUBLESHOOTING

All types of Netwrap will have operating problems at some time.

Mostly this is due to baling or crop conditions, or perhaps a mis-adjustment of the baler.

Below are a list of the most common Netwrap problems with recommended actions to find a solution.

Net not feeding

- Feed rollers not adjusted correctly

- Ensure rollers are tightly together and adjusted uniformly

- In-correct netwrap brake tension

- Check netwrap brake tension is correctly set

- Netwrap roll jammed in net box

- Check core is not wet or damaged

- Check for obstructions in net box

- Poor cut from previous bale = un-even net feeding in

- Check brake tension to ensure clean cut of net

Net wrapping on feed rollers

- Long tails of net wrapping on rollers

- Bad cut from previous bale – check tension

- Feed rollers dirty or damaged

Net not spreading

- Poor netwrap brake tension

- Obstruction in net box or path of net feeding

- Long tails of net from previous bale pulling net in from the edge

- check netwrap brake tension to ensure clean cut

Bales Bursting

- Not enough netwrap on bale

- Netwrap inside bale (roulade) so only some of netwrap on bale surface

- Bale not coming out of baler fast enough – damaging net on bale surface

- Bale damaged on tailgate or kicker bar when ejected

- Netwrap spread too wide on bale, going over the edge and pulling Franze tapes apart